Medical Technology & Analysis

Dosing aid with App

Miniaturized Gateway Technology

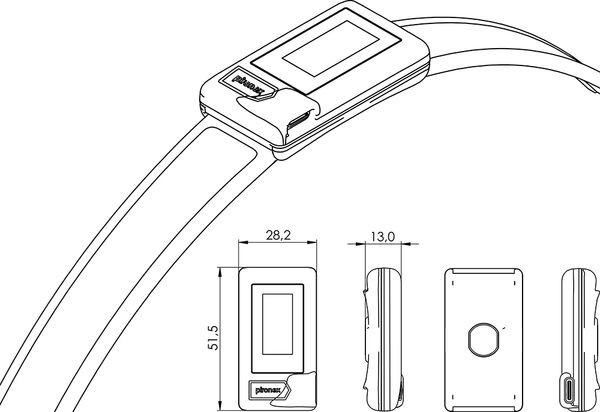

Advanced technology for precise body temperature measurement

Modern medical technology offers a variety of devices that enable precise diagnoses and research. An innovation in this field is the heat measurement device, specifically designed for accurate body temperature measurement. This device is characterized by its high precision and reliability. The heat measurement device uses highly accurate sensors for precise skin temperature measurements. It is compact and wearable on the wrist, making it extremely versatile in application. The ability to set individual threshold values and read the measured data on a display makes it particularly user-friendly. Additionally, the device is equipped with a rechargeable power source that ensures a long runtime.

Software for maximum flexibility

The associated software for the heat measurement device enables comprehensive parameterization and data transmission. Through a data interface, sensor correction values can be adjusted, and threshold values for temperature measurement can be set. The software also allows for the setting of time zones and temperature offsets, making it easy to adapt to various user requirements.

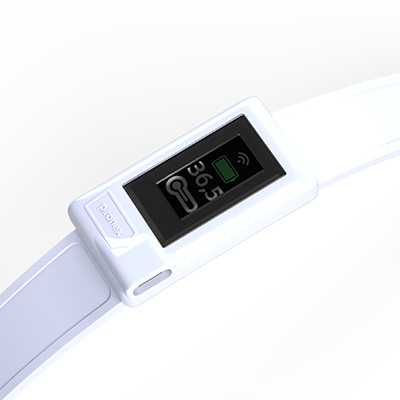

User-friendly display interface

A key component of the heat measurement device is the display. The display shows the measured temperature in real-time and indicates when adjustable threshold values are exceeded. This ensures that the user is immediately informed of critical temperature changes. Depending on the surrounding situation, the display can be dimmed or turned off to save energy and extend the device's runtime.

Precise NTC sensor and microcontroller

The sensor for determining body temperature consists of electronics integrated into the housing, which is worn on the wrist. A small NTC sensor continuously measures the skin temperature. An embedded microcontroller processes the data and calculates the temperature. The housing is lightweight and comfortable, enhancing wearability and allowing for continuous monitoring.

Energy efficiency and long runtime

Smart Dosing Aid for Medicines

In our interdisciplinary project teams from a wide variety of engineering disciplines, there is an intensive and regular exchange between designers and developers. The close cooperation results in creative solutions during the product design, which can also be produced cost-effectively in the end.

The ergonomic design and intelligent sensor technology make the dosing aid a functional product. Whether in chemistry, biology or in the household, the combination of smart electronics and an intuitive app makes the dosing aid an all-round product. The dosing aid is operated with the thumb. When the lid is closed, excess amount is wiped off and accurate dosing is ensured. In connection with the app, spoons and tipping processes are recorded, visualized and controlled accordingly.

Targeted quantity recording by counting and recording an actual "spooning process".

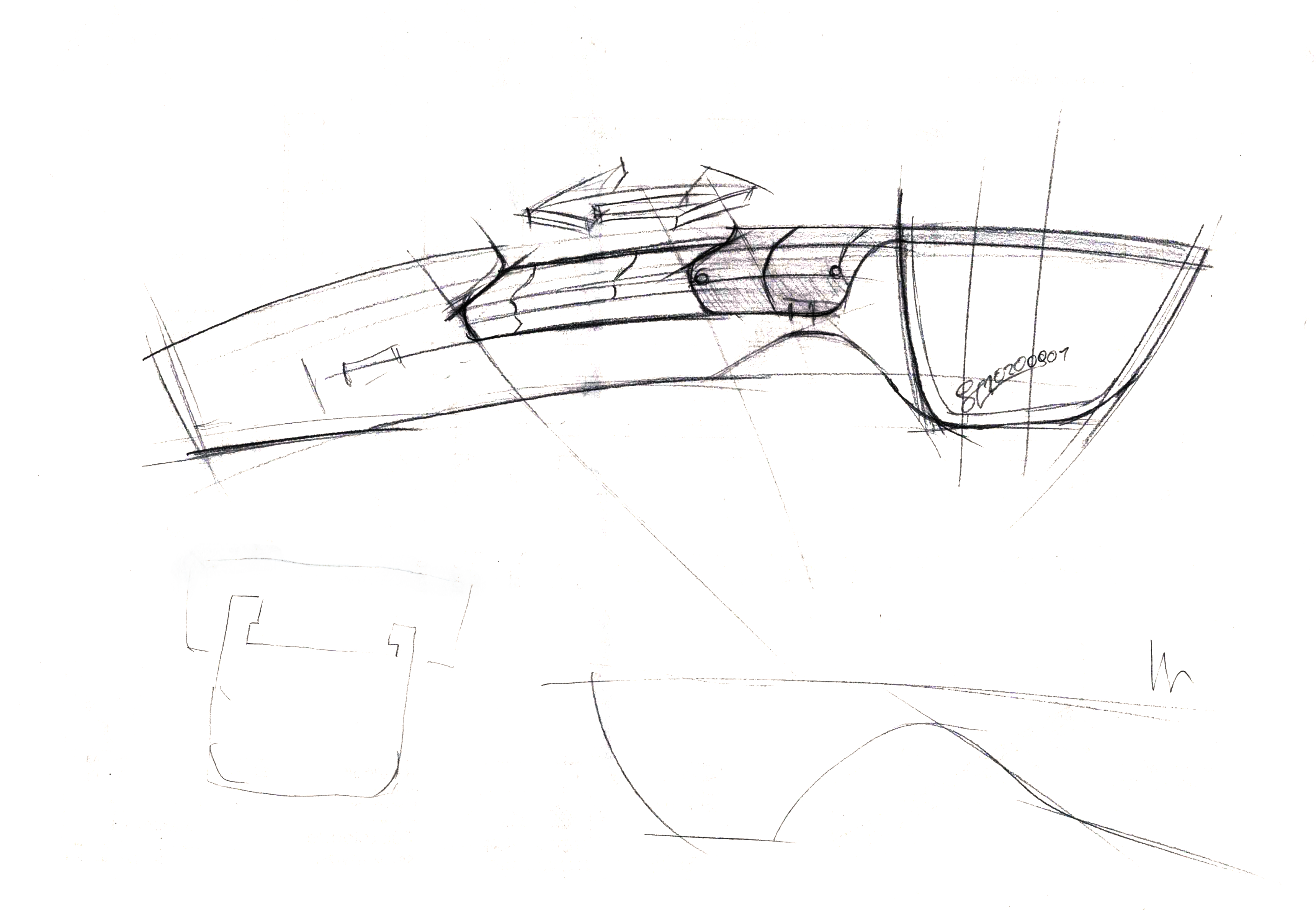

Case Design

Our employees have developed the design concept with the basic requirements for the product (design, function, ergonomics, etc.). In addition to aesthetic functions, functional requirements for usability, manufacturability and service life were also taken into account. A selection of concepts for the innovative product was created in the form of sketches and renderings.

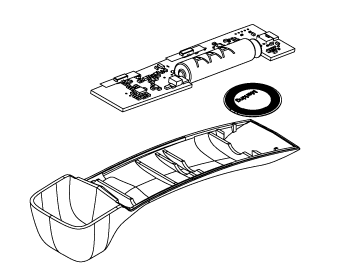

CAD Construction

Parallel to the design draft, a manufacturing and construction concept was developed. From the component separation to the complete installation space arrangement (package), all design-relevant details (such as circuit board attachment, battery holder or antenna guide) were constructed and specified three-dimensionally in CAD. This resulted in native data sets that could be further processed directly.

Functional Models

In the next step, functional models were made that represent the result in a tangible way and create opportunities for form and function testing. Thanks to our in-house 3D printer, we were able to hold the dosing spoon in our hands in just a few hours. The circuit boards fitted in our production department fitted perfectly. The functional software also worked as planned and the connection to the native app could be established.

UX UI Design

The native apps for iOS and Android guide the user through the setup and subsequent dosing process. By tilting the spoon and closing the lid, the administered amount is measured. The relevant quantity calculations are carried out in the dosing unit itself and displayed on the screen. The UX UI design process was crucial in this project, as the users are rather inexperienced with smart technology.