Automation & Control

Leakage sensor for manufacturing plants

Ultrasonic monitoring

Real-Time-Locating-System

Asset Tracking (RTLS)

Precise temperature control and energy optimization

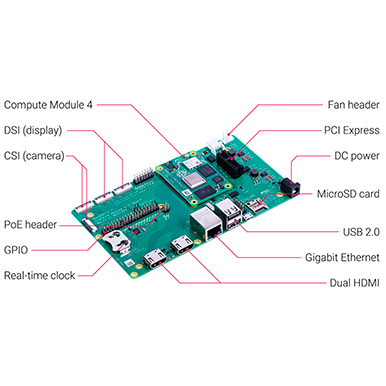

The development of Raspberry Pi for baseboards enables a wide range of projects. The Raspberry Pi is characterized by its small size, low cost, and low power consumption. These features make it ideal for applications ranging from smart home automation to the development of IoT applications. By using GPIO pins, various electronic components can be directly connected and controlled, making the Raspberry Pi a flexible and powerful tool for electronic projects.

Another feature of the Raspberry Pi is its versatility, supported by a large community that provides numerous resources and projects. Whether as a media center, small home server, or a platform for learning programming and electronics, the possibilities are almost limitless. Additionally, using the Raspberry Pi as a control unit allows for the development of energy efficiency algorithms that optimize the energy consumption of heating systems. Custom developments enable the continuous monitoring of consumption data and the adjustment of heating output according to current requirements, achieving significant energy savings.

Development of Raspberry Pi for baseboards

The Raspberry Pi Compute Module 4 (CM4) combines the powerful 64-bit quad-core CPU of the Raspberry Pi 4 with a smaller form factor, making it ideal for integration into custom hardware projects. It supports dual displays at 4K, hardware video decoding up to 4Kp60, up to 8 GB of RAM, Gigabit Ethernet, USB 2.0, as well as optional wireless LAN and Bluetooth 5.0 connectivity, and integrated eMMC storage up to 32 GB.

Precise temperature control

The resistance controller utilises the flexibility of the Raspberry Pi to execute complex control algorithms and process sensor data in real time. Customised developments facilitate precise temperature control and enable efficient use of heating systems by directly connecting and controlling sensors and actuators.

Versatile connectivity

Manufacturer-independent integration is facilitated by Raspberry Pi's flexibility. It integrates various components and interfaces, enabling heating control systems to connect with a diverse array of devices and systems, irrespective of the manufacturer. This enhances compatibility, adaptability, and maximizes the efficiency of existing infrastructures.

Simplified networking

Raspberry Pi offers a variety of interfaces, including Raspberry Pi with Modbus TCP, Modbus RTU and MQTT, which enable seamless integration into existing networks and systems. This ensures that heating control systems can easily communicate and exchange data with other devices and systems, simplifying the control of heating systems.

Customised development

Custom developments for Raspberry Pi provide tailored solutions for specific use cases. Whether it's customization for specialized sensors or the integration of custom interfaces, flexible solutions are offered that precisely meet the needs and requirements of customers.

Compressed Air Leak Detection in Industry

Significant costs are incurred annually due to compressed air leaks, especially in manufacturing plants. These leaks not only result in financial losses but also harm the environment through increased energy consumption and wear on the connected compressor.

The rapid and reliable detection of new leaks requires the use of an industrial leakage sensor, especially when multiple machines are equipped with compressed air components. Implementing sensors based on ultrasonic technology enables faster identification and elimination of leaks. The captured data is transmitted via Wi-Fi to a central server and analyzed on the server side. The sensor's costs quickly amortize through the energy savings of the compressed air system.

In contrast to leak detection using ultrasonic cameras or leak detection spray, the sensor continuously monitors leaks and is not limited to predefined maintenance intervals. This allows for a quicker response to new leaks and potential machine failures.

Energy Savings through Intelligent AI Sensors

The leakage sensor is specifically designed for industrial environments. It monitors critical points of the compressed air system, both in manufacturing plants, within the factory premises, and in the coverage area of the internal Wi-Fi network. Priority is given to monitoring vulnerable areas such as maintenance units, valve islands, constrictions, and distributors to identify a majority of potential leaks. Centralized configuration at the client's end allows for effective administration and leakage notification.

The integration of the sensor into manufacturing plants aims not only to detect and address leaks early but also to save energy and reduce maintenance costs. This is particularly relevant in facilities reliant on compressed air, such as factories with robotic arms.

Customizable to Your Requirements

Before the delivery of the leakage sensor, the Wi-Fi interface can be configured to establish a connection to the customer's Wi-Fi network at the respective property. Once the sensor is registered in the Wi-Fi network, all further configuration work can be centrally performed through a dashboard.

Communication with MQTT

After the on-site installation of the device, it automatically captures measurements according to a predefined rhythm and transmits them to the configured MQTT server. Adjustments to configurations and firmware updates can also be made through the dashboard.

Efficient Audio Transmission

A crucial factor in implementing the leakage sensor is the duration of the audio samples, which is only 100 milliseconds. This short timeframe not only ensures a quick and effective transmission of audio data but also has the advantage of protecting the privacy of employees near the device. This helps minimize privacy concerns.

Dashboard for Data

Additionally, a user-friendly dashboard is implemented. This serves as a central hub where operators can view all information. Through the integration of real-time data, the status of the sensors, current updates, and relevant information regarding detected leaks can be quickly grasped at a glance.

Indoor Positioning

The asset tracking system for indoor positioning enables the localisation of objects, vehicles and people in buildings and wherever GPS does not work reliably due to the lack of visual contact with the GPS satellites. The system offers a choice of different location methods and technologies and can be operated based on BLE, RFID or QR codes. The objects to be tracked are provided with appropriate beacons, tags or labels and recorded as soon as they are close to a gateway or send a signal to a gateway.

Asset Tracking

The "Asset Tracking" module of the pironex-iot.de platform offers a real-time overview of all registered assets and displays them on a map or in the form of a list. The platform offers a convenient search function that includes all device properties.

The dashboards can be adapted to customer needs. In this way, the current location of a specific device and/or any changes that have occurred can be traced at any time through various evaluations and forms of representation.

Gateways / Anchors

Depending on the case and on-site requirements, two different asset tracking gateways are available. piTerminal with a 4.3" display enables not only the reliable detection of RFID tags, but also professional human-machine interaction and can be used as a control computer or as a classic information terminal. The small piSmart-Gateway is battery-operated and location-independent.

Labels & Tags

Active BT beacons send signals (range of up to 30 m) with an individual identifier to the gateways at regular intervals. The detected position of the object is transmitted to the cloud. Passive RFID tags are recorded and evaluated by readers. Any object with an RFID tag is recognized as soon as it is close to a gateway with an integrated RFID reader.

App (iOS/Android)

The mobile native apps for Android or iOS map all functions of the online platform. In addition, the smartphones with the installed app can be used as asset gateways/anchors as part of the Real Time Locating System (RTLS). QR codes can be used in connection with the app. By scanning the QR code, the app reports the current position of the cell phone to the server.

Workflow

The pironex-iot.de platform enables active planning, control and logging of work-sharing processes within RTLS (Real-Time Locating System) projects. All tasks that have to be fulfilled when executing individual processes can be recorded and structured here. The use of industrial apps in the daily work environment has the advantage that the use of smartphone technology from the private environment, which workers are used to, is easy for industrial use.