(+49) 0381 7006080

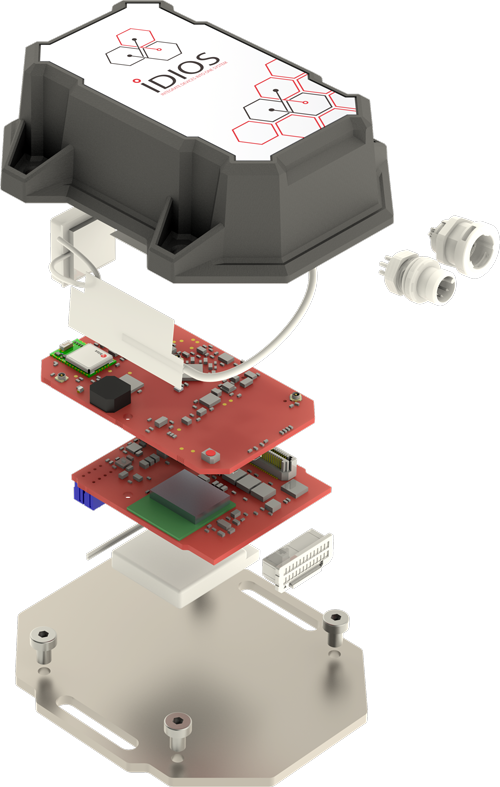

Design and Construction Housing

When it comes to a functional and modern housing for customer-specific electronics, it is important to have the right know-how in all manifacturing steps - from the first idea sketches, through technical design variants, to the elaborate design and 3D printing for the electronics housing.

The designers and constructors develop draft designs for innovative products or redesign existinging housings and technical constructions. The interaction of product design, construction and electronics development minimises the risk of errors in the final product.

Form Follows Function

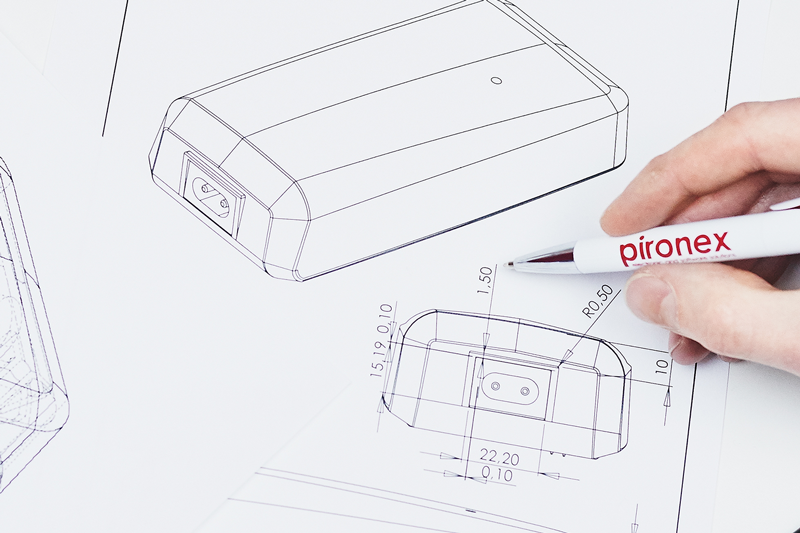

The development engineers, designers and constructors work together with the customer to develop a design concept with basic requirements (design, function, ergonomics, etc.) for the future product. In addition to aesthetic functions, functional requirements for usability, manufacturability and service life are also included. We always focus on your customers as well as target markets and keep the feasibility firmly in mind. In the form of sketches and renderings, a selection of concepts for the working product is created.

The preferred design is further refined, modelled and elaborated in detail using the 3D CAD program SolidWorks. The photorealistic 3D product visualisations give an accurate idea of what the product will look like when finished. At the same time, mock-ups (design prototypes) are created on request, which present the product in a tangible way and create opportunities for form and function testing. In the design process, we calculate all relevant housing parameters in terms of shape and material.

A prototype is the tangible vision of the product. Functional prototypes are used to test user-friendliness, material, assembly, maintenance, shape and functionality under real conditions.

In House Rapid Prototyping

pironex uses its own 3D printers (SLA and FDM) and milling machines to quickly and easily create components that can be used for test or for model construction purposes.

With rapid prototyping via 3D printing, you receive functional and resilient prototypes at short notice. In this way, problems and weaknesses are identified at an early stage, leading to the design or function being corrected before production.

Prototyping:

- SLA and FDM 3D printing

- Creation of resilient milled parts

- Functional samples for function and handling tests

- Functional samples for marketing purposes

Transition to the Serial Product

In the "Transition to the Serial Product" phase, the development engineers optimise the production of the product according to the needs and the available production possibilities.

The required customer-specific tools and moulds (e.g. injection moulding) for series production are developed and optimised with the production companies for injection moulding.

Preparation for series production:

- Creation of process-optimised technical drawings (single part, assembly and tolerance drawings)

- Handover of production documents for the customer

- Accompanying serial production at the service provider